In Scranton's competitive business landscape, Six Sigma and lean six sigma are powerful tools for success. These data-driven process improvement methodologies focus on defect reduction, enhancing efficiency and customer satisfaction by combining lean manufacturing waste minimization with statistical process control. Businesses that equip employees with Six Sigma Black Belt certification or specialized training can achieve remarkable results, setting new industry standards. Scranton serves as a prime example, with local businesses across sectors like healthcare and manufacturing achieving significant improvements in process efficiency, cost reduction, faster production times, and enhanced customer satisfaction through Six Sigma methodologies. Becoming a Six Sigma Black Belt involves an extensive learning journey focused on process improvement, starting with understanding the basics, completing training (including DMAIC methodology), and gaining certification, which opens career advancement opportunities as leaders in process improvement initiatives.

“Discover the transformative power of Six Sigma in Scranton, PA, through real-world case studies. This article explores how businesses have harnessed Lean Six Sigma methodologies to achieve remarkable results. From understanding the fundamentals and uncovering its benefits for local enterprises to delving into successful implementations and the path to becoming a Six Sigma Black Belt, we provide valuable insights. Learn from Scranton’s success stories and unlock the potential of Six Sigma certification for your organization.”

- Understanding Six Sigma: The Basics and Its Benefits for Scranton PA Businesses

- Real-World Applications: Exploring Successful Lean Six Sigma Case Studies in Scranton

- Becoming a Six Sigma Black Belt: Training, Certification, and Career Advancement Opportunities

Understanding Six Sigma: The Basics and Its Benefits for Scranton PA Businesses

In the competitive business landscape of Scranton, PA, understanding and implementing effective quality management strategies is crucial for success. One such powerful approach is Six Sigma, a data-driven methodology focused on process improvement and defect reduction. At its core, Six Sigma emphasizes identifying and eliminating root causes of defects, improving overall process efficiency, and enhancing customer satisfaction.

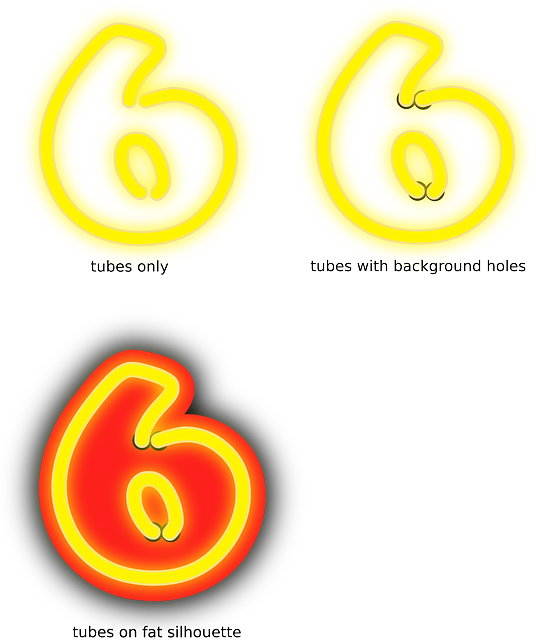

The Lean Six Sigma principles combine the lean manufacturing focus on minimizing waste with statistical process control techniques. This hybrid approach empowers Scranton businesses to streamline operations, reduce costs, and drive innovation. Earning a Six Sigma Black Belt certification or undergoing specialized training can equip employees with the skills needed to lead and implement these projects effectively. By embracing Six Sigma methodology, local enterprises can achieve remarkable results, setting new standards for excellence in their industry.

Real-World Applications: Exploring Successful Lean Six Sigma Case Studies in Scranton

In the real world, Scranton PA has witnessed remarkable transformations through the application of Lean Six Sigma methodologies. These case studies offer valuable insights for organizations aiming to improve processes and enhance efficiency. Scranton’s success stories showcase how Six Sigma principles, often coupled with a lean approach, can drive significant changes across various sectors. From healthcare institutions to manufacturing facilities, local businesses have embraced six sigma certification and training programs to achieve remarkable results.

The city’s case studies highlight the power of a structured problem-solving framework. By implementing six sigma black belt methodologies, organizations in Scranton have identified and eliminated waste, streamlined processes, and improved overall quality. This approach has led to reduced costs, faster production times, and enhanced customer satisfaction. Exploring these real-world applications not only demonstrates the effectiveness of Lean Six Sigma but also inspires other businesses to adopt similar strategies, ultimately fostering a culture of continuous improvement and excellence.

Becoming a Six Sigma Black Belt: Training, Certification, and Career Advancement Opportunities

Becoming a Six Sigma Black Belt involves an extensive journey of learning and practical application. It begins with understanding what is six sigma and its core principles, which focus on process improvement and defect reduction. The path to certification often starts with completing six sigma training, where aspiring Black Belts learn the lean six sigma methodology and tools such as DMAIC (Define, Measure, Analyze, Improve, Control). This training equips them with skills to lead projects and drive changes within organizations.

Certification itself is a significant milestone, recognizing individuals’ expertise in implementing Six Sigma strategies. Many professionals pursue this path for career advancement opportunities, as it opens doors to leadership roles in process improvement initiatives. Six Sigma Black Belts are highly sought after for their ability to streamline operations, enhance efficiency, and deliver measurable results, making them valuable assets to any organization embracing lean six sigma principles.

Scranton PA businesses can greatly benefit from adopting Six Sigma and Lean Six Sigma methodologies. As demonstrated by real-world case studies, these data-driven approaches can lead to significant process improvements, cost savings, and enhanced customer satisfaction. Earning a Six Sigma Black Belt certification through proper training and education is key to leading such initiatives successfully. By embracing these principles and investing in continuous improvement, Scranton’s business landscape can continue to evolve and thrive in today’s competitive market.